Ultra Microsilica

"Magic Durabuild Material Pvt Ltd (Formerly known as SR Group - Highway Supplies and Network Pvt Ltd) continues to provide the same trusted service across our entire product range. You can rely on our expertise."

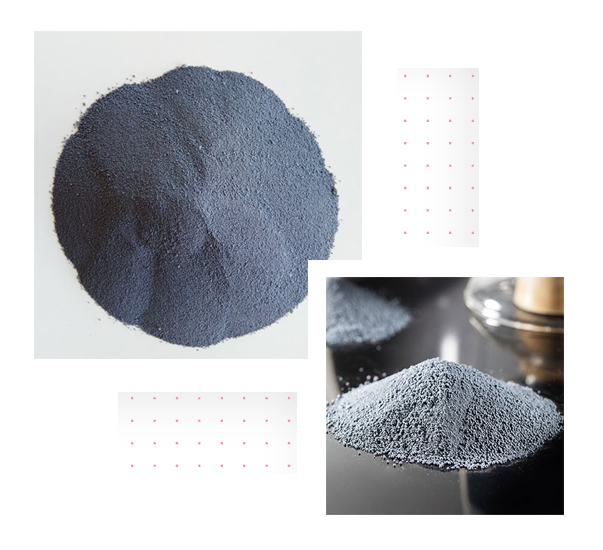

Microsilica Powder form

Ultra Micro Silica is composed of silicon dioxide (Si02), collected from silicon metal and ferrosilicon. Ultra Micro Silica will react with the Calcium Hydroxide from the cement, which will form more of the Calcium Silicate hydrate, increasing the strength of the concrete. Using Ultra Micro Silica will also increase the durability of the concrete.

Description

Ultra Micro Silica a Dark gray Powder

Shelf life:- 1 Year

Physical and Chemical properties

Appearance : dark gray Powder

Ultra Micro Silica is composed of silicon dioxide (Si02), collected from silicon metal and ferrosilicon. Ultra Micro Silica will react with the Calcium Hydroxide from the cement, which will form more of the Calcium Silicate hydrate, increasing the strength of the concrete. Using Ultra Micro Silica will also increase the durability of the concrete.

Description

Ultra Micro Silica a Dark gray Powder

Shelf life:- 1 Year

Physical and Chemical properties

Appearance : dark gray Powder

Colour : dark Gray

Key Benefits

- Precast usage

- Produces high early and higher ultimate compressive strengths

- Eliminates steam curing, saving on heating costs

- Shotecrete usage

- Less material wastage and greater efficiency of product use

- High impermeability and significantly less rebound loss

- Protects reinforcing steel from corrosion

- Improved bonding strength

- Thicker applications with each nozzle pass and enhanced pumpability

Typical Applications

- High performance concrete

- Precast concrete

- Spray applied concrete

- Concrete exposed to environmental and chemical attack

- Marine concrete

- Ready mix concrete for high strength concrete

Typical Applications

| Component | Silicon metal |

| (% by Weight) | Production |

| Sio2 | >90% |

| CI | 0.09 -0.2% |

| Available Alkalis | 0.5 -1.5% |

| Loss on Ignition | 2.0 -4.0% |

| Moisture Content | 0.1-0.35% |

| Particle Size | 0.03 – 0.15 microns |

| Retained on 325 Sieve (45 micron) | 04-10% |

| Surface area (BET method) | 15-28 m2/g |

| Dry bulk density (densified) | 500 – 650 kg/m3 |

Storage

Ultra Micro Silica should be stored at room temperature (min 10°C and max 35°C), kept dry and out of direct sunlight. If these conditions are maintained and the product packaging is unopened, then a shelf life of 1 year can be expected.

Application Guidelines

Dosage can be adjusted to meet various mix design requirements or to specific job site conditions. Trial concrete or grout mixes must be carried out to determine the appropriate dosage.

Typical dosage is between 5% and 15% of cementitious powder content.

Health & Safety

Ultra Micro Silica should only be used as directed. We always recommend that the Safety data sheet is carefully read prior to application of the material. Our recommendations for protective equipment should be strictly adhered to for your personal protection. The Safety data sheet is available upon request from your local HOWTPL representative.

Ultra Micro Silica is composed of silicon dioxide (Si02), collected from silicon metal and ferrosilicon. Ultra Micro Silica will react with the Calcium Hydroxide from the cement, which will form more of the Calcium Silicate hydrate, increasing the strength of the concrete. Using Ultra Micro Silica will also increase the durability of the concrete.

Description

Ultra Micro Silica a Blue Granule

Shelf life:- 1 Year

Physical and Chemical properties

Appearance : Blue Granule

Key Benefits

- Precast usage

- Produces high early and higher ultimate compressive strengths

- Eliminates steam curing, saving on heating costs

- Shotecrete usage

- Less material wastage and greater efficiency of product use

- High impermeability and significantly less rebound loss

- Protects reinforcing steel from corrosion

- Improved bonding strength

- Thicker applications with each nozzle pass and enhanced pumpability

Typical Applications

- High performance concrete

- Precast concrete

- Spray applied concrete

- Concrete exposed to environmental and chemical attack

- Marine concrete

- Ready mix concrete for high strength concrete

Typical Applications

| Component | Silicon metal |

| (% by Weight) | Production |

| Sio2 | >92% |

| CI | 0.09 -0.2% |

| Available Alkalis | 0.5 -1.5% |

| Loss on Ignition | 2.0 -4.0% |

| Moisture Content | 0.1-0.35% |

| Particle Size | 0.03 – 0.10 microns |

| Retained on 325 Sieve (45 micron) | 04-10% |

| Surface area (BET method) | 15-30 m2/g |

| Dry bulk density (densified) | 550 – 700 kg/m3 |