Concrete Fiber Range

"Magic Durabuild Material Pvt Ltd (Formerly known as SR Group - Highway Supplies and Network Pvt Ltd) continues to provide the same trusted service across our entire product range. You can rely on our expertise."

Polypropylene Monofilament Fibre for concrete reinforcement that complies With Standard Specification for Fibre Reinforced Concrete and Shotcrete, and is specifically designed to help mitigate shrinkage cracking in concrete. Typically used dosage rate of 0.6 to 0.9kg/m3 but special applications can use dosage upto 3kgtcum., it’s have been shown to greatly reduce shrinkage cracking by as much as 80% when compared to plain concrete.

Features

- Crack control

- Improved Toughness

- Reduced Permeability

- Improved Abrasion resistances

- Reduced Shrinkage

- Improved Flexural & tensile strength

Application / Uses

- RCC / PCC / PQC / Ramps / Retaining Walls

- Slab on grade

- Tunneling

- Zetties

Features

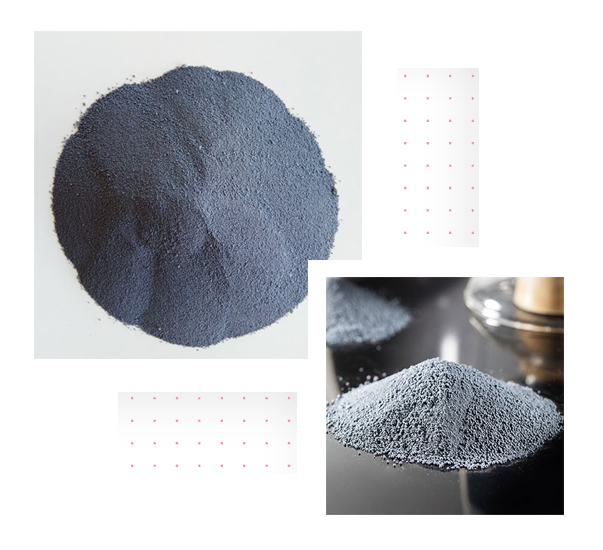

Ultra Micro Silica is composed of silicon dioxide (Si02), collected from silicon metal and ferrosilicon. Ultra Micro Silica will react with the Calcium Hydroxide from the cement, which will form more of the Calcium Silicate hydrate, increasing the strength of the concrete. Using Ultra Micro Silica will also increase the durability of the concrete.

Description

Ultra Micro Silica a Dark gray Powder

Shelf life:- 1 Year

Physical and Chemical properties

Appearance : dark gray Powder

Colour : dark Gray

Typical Applications

| Particulars | Unit | Specification |

| Material | 100% Virgin Polypropylene | |

| Shape | Circular / Non Circular | |

| Diameter | Micron | 12-35 |

| Tensile Strength | MPA | >400 |

| Elongation | % | 30-60 |

| Length | mm | 3 / 6 / 12 / 18 / 24 |

| Moisture Flat | % | <1% |

| Melting Point | C | >160 |

| Specific Gravity | Gm / cc | 0.91 |

| Codes Adherence |

IS 16481 : 2016 |

Storage

Ultra Micro Silica should be stored at room temperature (min 10°C and max 35°C), kept dry and out of direct sunlight. If these conditions are maintained and the product packaging is unopened, then a shelf life of 1 year can be expected.

Application Guidelines

Dosage can be adjusted to meet various mix design requirements or to specific job site conditions. Trial concrete or grout mixes must be carried out to determine the appropriate dosage.

Typical dosage is between 5% and 15% of cementitious powder content.

Health & Safety

Ultra Micro Silica should only be used as directed. We always recommend that the Safety data sheet is carefully read prior to application of the material. Our recommendations for protective equipment should be strictly adhered to for your personal protection. The Safety data sheet is available upon request from your local HOWTPL representative.

POLYPROPYLENE MACRO FIBRE

Polypropylene Macro Fibre is with deformed surface for concrete reinforcement that complies with standard specifications for Fibre Reinforced Concrete. Specifically, this custom made Macro Fibre is designed to infuse Concrete With high added levels of Energy Absorption, Toughness, Durability & to increase the Post Cracking Residual Strength of the Concrete to increase durability of concrete. Typically used dosage rate of 3-8 Kg/m3. This can replace steel fibre also

Features

- Increase flexural toughness

- Increase ductility in concrete

- Concrett deflection under control as per dosage in every absorption

- Increase durability

- Can replace steel fiber / nominal steel

- Improve elasto-plastic behavior

Application / Uses

- Shortcrete in tunnel, Concrete Liners rocks support

- PQC (Pavement Quality Concrete) Industrial Floorings and Slab on Grade

- Precast

- Zetties

Typical Applications

| Particulars | Unit | Specification |

| Material | 100% Virgin | |

| Polypropylene | Non Circular | |

| Shape | Non Circular | |

| Diameter | mm | 0.80-0.90 |

| Tensile Strength | MPA | >500 |

| Cut length | mm | 40 – 65 |

| Specific Gravity | Gm / cc | 0.91 |

| Young’s Modules | >6000 | |

| Aspect Ratio | >40 | |

| Alkali Resistance | Excellent | |

| Melting Point | C | >160 |

| Water Absorption | >Nil | |

| Codes Adherence | >EN – 14889-2 | |

| Quality Assured | >ISO 9001 :2015 | |

| Packing | >Water Soluble Pucks | |

| Dosage | Kg / cum | 3-9 |

POLYESTER MICRO MONOFILAMENT FIBRE

Polyester Micro Monofilament Fibre is a Monofilament Non Circular / Circular Fibre for concrete reinforcement that complies With Standard Specification for Fibre Reinforced Concrete and Shotcrete. and is specifically designed to help mitigate the formation of shrinkage cracking inconcrete. Typically used at a dosage rate of 0.9 kg/m3 With special designed dosage for special applications. it’s have been shown to greatly reduce shrinkage crackingby as much as 80% when compared to plainconcrete.

Features

- RCC / PCC / PQC / Retaining Walls / Ramps

- Water Retaining Structures

- Slab on grade

- Tunneling

- Canal Linnings

- Screed / Mortar

Application / Uses

- RCC / PCC / PQC

- Slab on grade

- Tunneling

- Canal Linnings

- Screed / Mortar

Typical Applications

| Particulars | Unit | Specification |

| Material | 100% Virgin Polyester | |

| Shape | Circular / Non Circular | |

| Diameter | Micron | 12-35 |

| Tensile Strength | MPA | >400 |

| Elongation | % | 40 – 60 |

| Length | mm | 3 / 6 / 12 / 18 / 24 |

| Moisture Flat | % | < 1% |

| Melting Point | C | >40 |

| Alkali Resistance | Excellent | |

| Melting Point | C | >160 |

| Water Absorption | >Nil | |

| Codes Adherence | >EN – 14889-2 | |

| Quality Assured | >ISO 9001 :2015 | |

| Packing | >Water Soluble Pucks | |

| Dosage | Kg / cum | 3-9 |